ATTiny85 First Sketch

First successful try with ATTiny85, programmed through an Arduino UNO. Followed instructions found here

First successful try with ATTiny85, programmed through an Arduino UNO. Followed instructions found here

This robot can run through two types of circuits, one that involves a Voltage Trigger and another that involves Diodes (Zener or Signal). In the end we decided to go with the Signal Diode circuit.

The electronic components in this BEAM Solar robot are: Voltaic 2W - 6V Solar panel, a 1F Capacitor, a 6V and 280 mA DC motor, PNP Transistor (2N3906), two Signal Diodes (in series), 2.2K Ω resistor and NPN Transistor (2N2904). How this circuit works is the Capacitor charges until the PNP transistor (06) receives base current through the Signal Diodes and turns on. The NPN transistor (04) turns on and the capacitor is discharged through the motor. As the NPN turns on, the 2.2K resistor starts to supply base current to the PNP and the circuit snaps on. When the capacitor voltage drops below about 1V, the the PNP turns off, the NPN turns off and disconnects the motor from the capacitor which starts to charge up again.

We changed to this motor once we fail trying out a High Efficiency motor (4V and 30mA). Despite this change, the overall torque from the 6V Motor (± 180 gm/s^2) and 1.4cm radius wheels still isn't enough to drive the entire rig (circuit, plastic disc and plastic sphere). Next steps could be getting a more powerful motor, or make the entire robot lighter.

What could be a way to log ITP's entrance and see the difference between the elevators' use and the stairs'? Through a solar powered DIY Arduino, we decided to visualize this data (and store it in a .csv table) in the screen between the elevators at ITP's entrance.

After creating a DIY Arduino that could be powered through solar energy, by following Kina's tutorial we were able to set a basic solar rig that would charge the 3.7V and 1200 mA LiPo battery. We connected the solar panels in series and ended up with an open circuit voltage of 13V. Our current readings however, were of 4 mA.

We hooked the Arduino data to a Processing sketch that would overwrite the table data of a .csv file every second. All of the code can be found in this link.

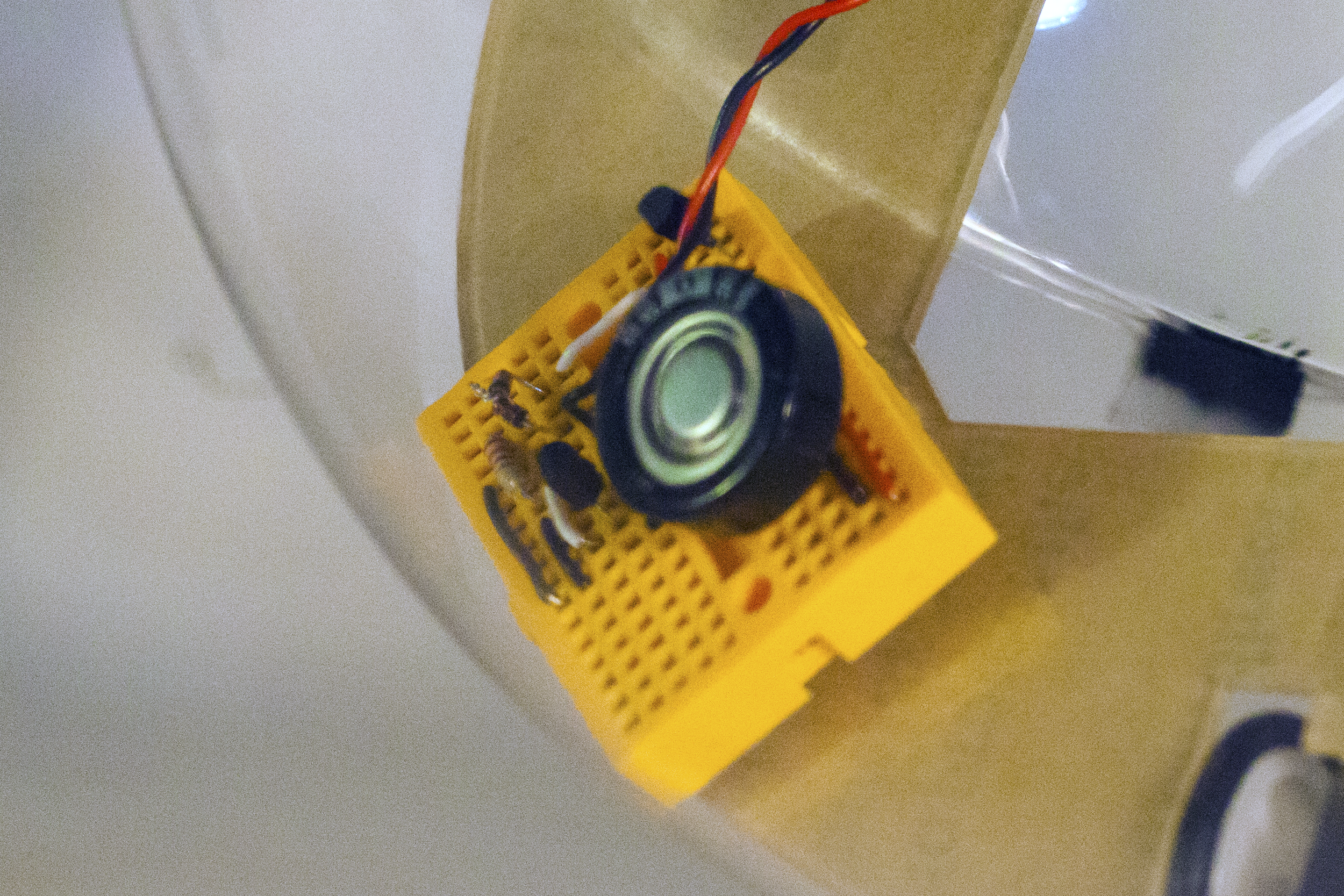

How can a fabricated object have an interactive life? The M-Code Box is a manifestation of words translated into a tangible morse code percussion. You can find the code here and what's needed to create one M-Code Box is an Arduino UNO, a Solenoid Motor (external power source, simple circuit) and a laptop with Processing.

There are two paths to take this project further. One is to have an interpreter component, recording its sounds and re-encoding them into words, like conversation triggers. The second is to start thinking on musical compositions by multiplying and varying this box in materials and dimensions.

This project came upon assembling two previous projects, the Box Fab exploration of live hinges and the Morse Code Translator that translates typed text into physical pulses.

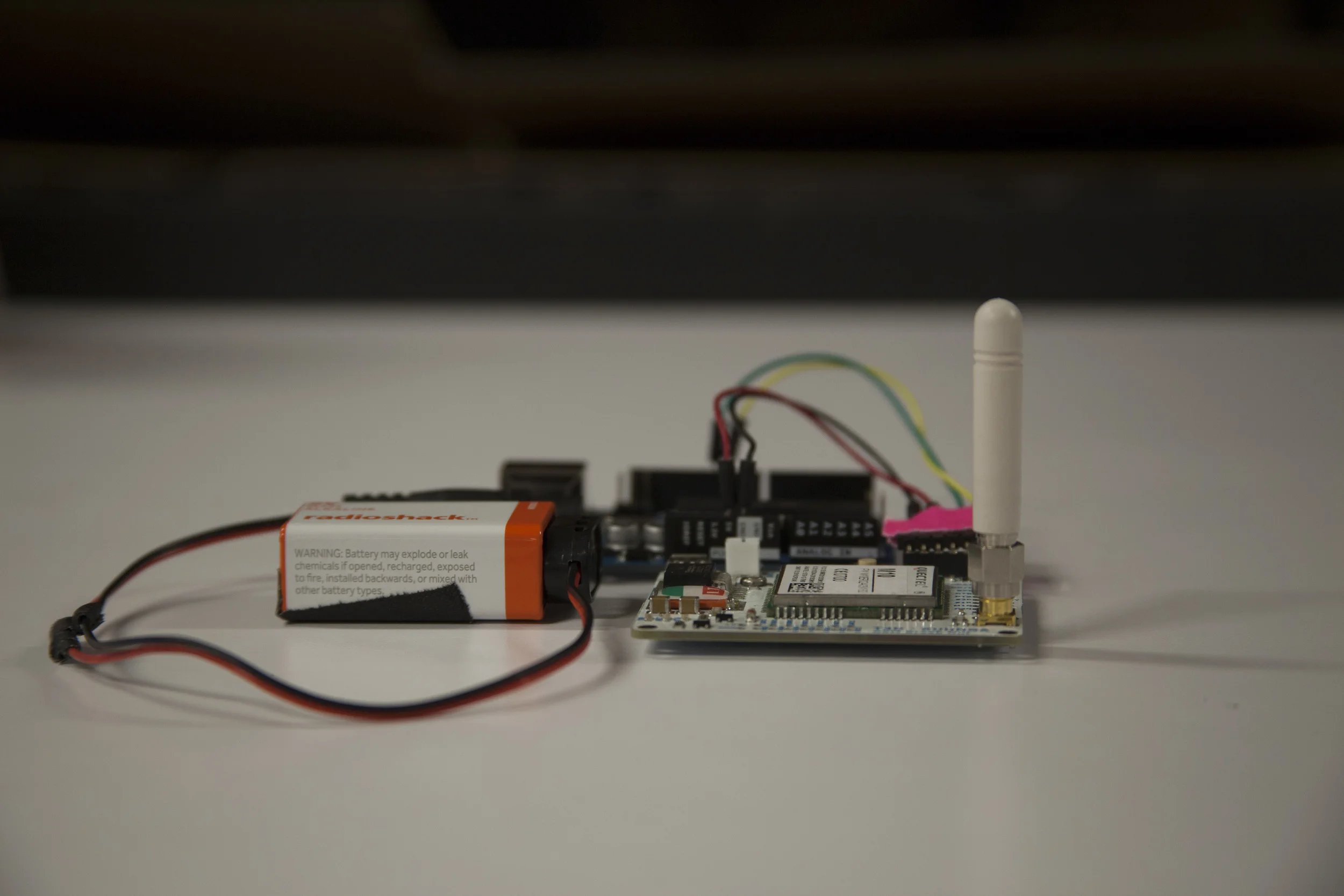

For our GSM class final, partnered with Clara and Karthik we created a Geo-Fence hooked to an Arduino Uno.

If you're receiving garble when reading the incoming data from the GSM through Arduino, you should check whether both boards are working at the same baudrate (9600). To change the GSM board –Quectel 10M– baudrate through an FTDI adaptor and CoolTerm:

Now plug the GSM Board to the chosen Software Serial PINS (10 and 11) and change the Fence center-point (homeLat and homeLon) the size –radius– of the fence in KMs (thresholdDistance) and the phone is going to be controlled from (phoneNumber), UPLOAD and run the SERIAL MONITOR. The code can be found in this Github Repo. Enjoy

The hardware used for this project was an Arduino UNO and one of Benedetta's custom GSM Boards with enabled GPS. This setup could work for potentially stand-alone purposes, however is advised to make sure beforehand that the power source has enough Watts to run the setup for the sought time.

Along Oryan Inbar, we decided to address the kinetic energy challenge by powering the LED through a trainer bicycle setup. After repurposing the stepper motor from a bill-printer we began exploring different circuit possibilities around capacitive, resistor and charging settings. In the end our circuit is composed by the two rectified-coils from the stepper connected in series, a two way switch that allows to charge the capacitors first and light the LED after, three 1F Capacitors, one 330 Ohm resistor and a counter LED (which we believe is lit by 1.7 Volts)

It was surprising to see the Short Circuit Voltage whenever plugging the LED, from around 29V to 2.2V. We also decided to add up the two coils to two Bridge Rectifiers that would power the circuit in series. This and the overall capacitance pointed that we needed to first charge the capacitors before connecting the LED. This is the reason behind the two way switch. After sorting the general circuitry, we decided to use the strongest muscles as the source of power along with an already solved solution as the mechanism –a bicycle–.

We created a bicycle trainer to interface the bicycle to the stepper motor. This latter one we re-use it from a bill-printer taken from the shop's junk shelf. The overall kinetic energy inputed into the stepper motor can be identified from the gear configuration. We re-use the embedded gear system from the printer and realized that the driver has a 11:1 ratio in relation to the driven motor gear. At the same time, this gear system, specifically its driver was connected to the back wheel from the bike, having more less a 1:35 ratio.